ITER requires an extensive diagnostics system to monitor the experiment. Sensors will be located in its vacuum vessel to measure the temperature, irradiation, composition of the plasma. Cables will carry the signals produced by the sensors through the walls of the vacuum vessel so that experts can analyse the data.

The Spanish SME VAC-TRON together with IDOM have been involved in the development of the In-vessel electrical feedthrough of ITER. Working with F4E pushed the companies to their technical limits and encouraged them to innovate in their design and fabrication process. Thanks to Glass-to-Metal Sealing (GTMS) technology, it has been possible to produce a hermetic seal which sustain a temperature of 300°C and a pressure up to 2500 bar.

Safer energy supply for pumps and compressors in gas industry thanks to GTMS

The connector was based on a bespoke design based on GTMS connectors on a batch furnace combined with new heating profiles and materials opening the possibilities to manufacture connectors without size limitation and for different types of signals. This development required significant effort for the design, manufacturing, testing and qualification to cope with all the functional and nuclear safety requirements of ITER. “We are very satisfied with VAC-TRON’s expertise and commitment during our project and delighted to see how investment in fusion energy can have a quick return on other industrial sectors,” says Miguel Perez Lasala, F4E Diagnostics Project Officer.

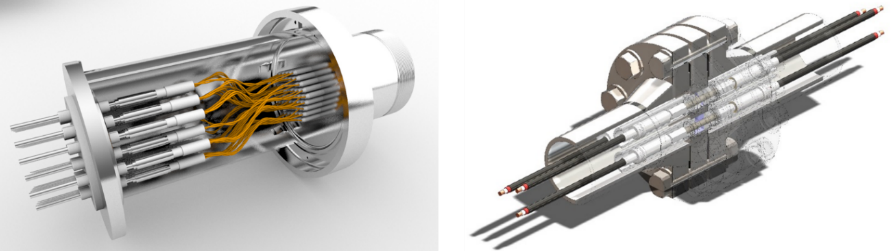

Figure 1. In vessel Feedthrough (Letf) Oil & Gas 45 to 75 kW Feedthrough (Right). (Source:IDOM)

Based on the knowledge acquired in the process, the team has succeeded in creating products for other applications with similar needs in demanding environments like the Oil & Gas market. The main applications will be to secure the energy supply for pumps and compressors in the gas industry. The application of the technology beyond the fusion market has required technical adaptations on the design and the production of the connectors. The first pieces will be produced in 2021 and VAC-TRON will continue to work in order to obtain certification from different entities like ATEX, IECEx.

Working with F4E helped increasing the value and scope of of VAC-TRON products

Without the F4E contract, VAC-TRON recognises it would have been impossible to meet the requirements of Oil and Gas industry. The collaboration encouraged the SME to invest in new equipment and develop technical expertise for larger components. Switching from a “Continuous furnace process” to “Batch Stationary furnace process” allowed them to work on component with a diameter up to 250mm (instead of 20mm before) and to develop new know-how. There was also an impact on value creation and jobs: from a core business line based on millions of pieces sold for few euros per piece, VAC-TRON can now enter into a new market with a value estimated at few thousands per piece.

VAC-TRON expects to grow rapidly during next 5 years and triple its turnover by 2026. With the development of these new products it is considered that both VAC-TRON and IDOM will be able to take part in challenging projects in fields like Oil&Gas, space, nuclear, big science.